apparatus for laboratory and pilot plant

Heat exchangers, filter chutes, columns, condensers, ...

CAD design and manufacture of high quality process equipment such as distillation bridges, heat exchangers, phase separators, receiver vessels.

Use our pool of proven apparatus or give us your requirements. Pressure, temperature, material - the choice is yours.

In addition to our proven apparatus for laboratory and pilot plant, we also offer:

- Prototypes, one-offs and small batches

- On request with complete piping and pre-assembly

- made of stainless steel and special materials such as Hastelloy®.

- for research & development and small-scale production

-

for the chemical, pharmaceutical, petrochemical and food industries

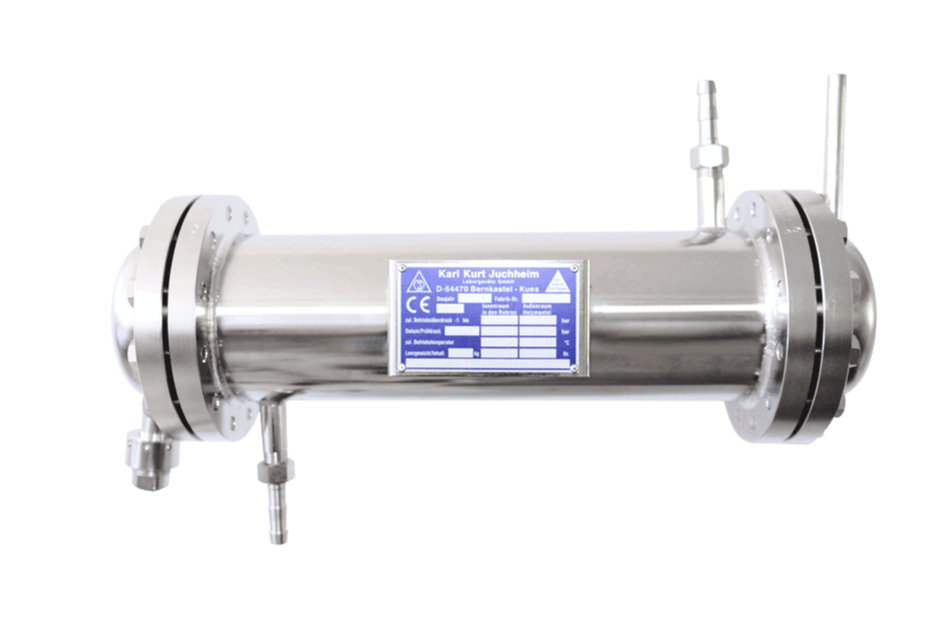

Shell and tube heat exchanger up to 450°C and 100 bar. Also with condensate drain.

With our modular system, we implement your requirements. From vacuum to high pressure processes. Standard exchange area: 0.16m² or 0.32m². Individually up to 10m² possible.

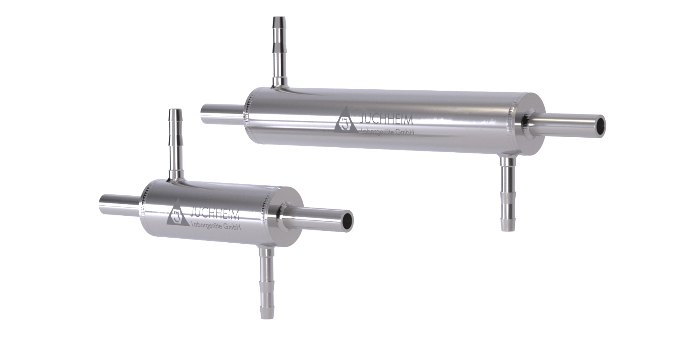

Small gas coolers

Also for hydrogen.

Compact design: dimensions from D=35mm, L=150mm plus connections.

Connections selectable: e.g. cutting ring fitting (Swagelok)

Up to 400°C and 100 bar

The direct path to the solution:

We will take care of the rest.

Reservoir 200 ml to 100 liters and max. 300 bar. Optionally also heated, cooled, stirred.

With our modular system, we implement your requirements. From vacuum to high-pressure processes.

Take the first step.

We will take care of the rest.

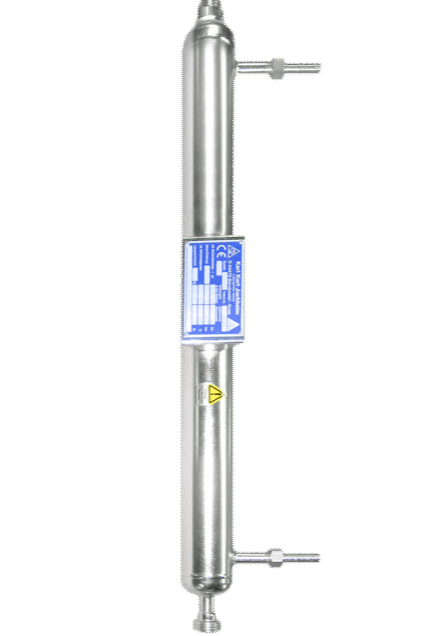

Liebig cooler up to 400 bar, 450°C. Reflux condenser for the pressure reactor.

With our modular system, we implement your requirements. From vacuum to high-pressure processes.

Take the first step.

We will take care of the rest.

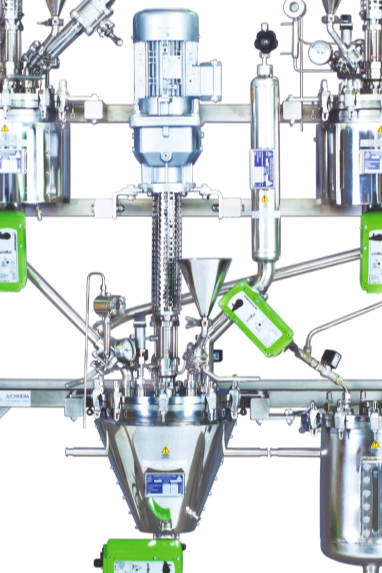

Individual devices, functional assemblies or even an entire plant.

With our modular system, we implement your requirements. From vacuum to high-pressure processes.

100 % Zertifizierte Werkstoffe

Our pressure equipment is made exclusively using tested materials with certificate - for your safety

CE nach DGRL 2014/68/EU

Our pressure equipment are made according to the pressure equipment directive.

Zertifizierte Schweißverfahren

We are regularly recertified to weld stainless steel and nickel-based alloys (hastelloy)

100% in Deutschland produziert

high quality, environmentally and socially responsible

Take the first step.

We will take care of the rest.