Mixing technology | agitator systems

the little things make the difference

JUCHHEIM has a wide portfolio of stirrer drives, stirrer elements, stirrer feedthroughs, and accessories that enable optimal adaptation of this important function to the specific application.

JUCHHEIM agitators are used in the fields of chemicals, biotechnology, pharmaceuticals, cosmetics, paints and coatings, plastics, biofuels, waste water, basic materials, foodstuffs, mineral oils & fats, paper and pulp, and metal processing.

Depending on the application, different designs are required. Agitators in ATEX design allow the use in explosive environments.

Agitators

the little things make the difference

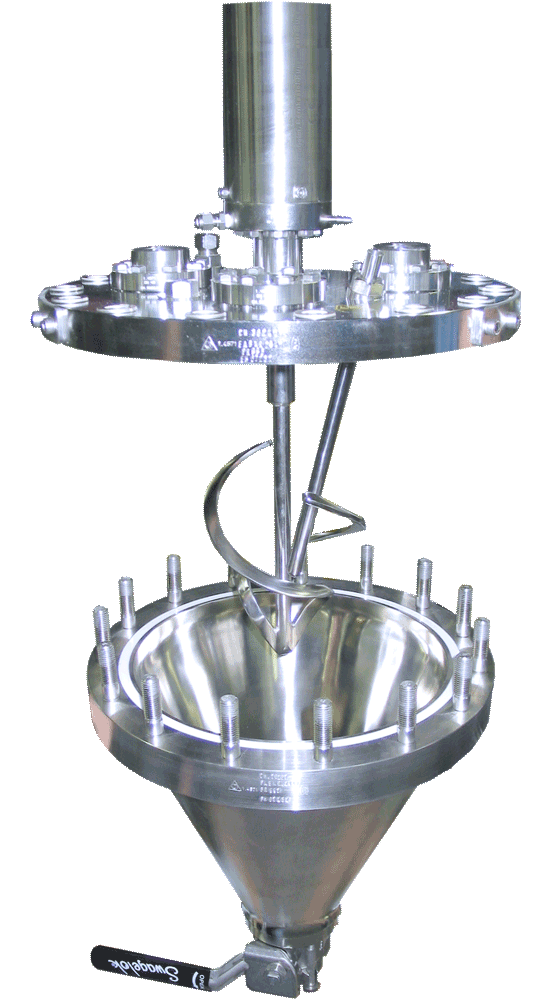

In addition to the standard stirrer shapes, JUCHHEIM also manufactures any stirrer geometries made of stainless steel or Hastelloy® according to your requirements.

The stirring elements or stirring blades can be provided with a PTFE or tantalum coating if required.

For wall-mounted stirrers, we also supply them with wipers made of PTFE or PEEK. These can be easily replaced after possible wear.

We also have gassing stirrers in our program, e.g. for hydrogenation. We are also happy to carry out preliminary tests on our premises.

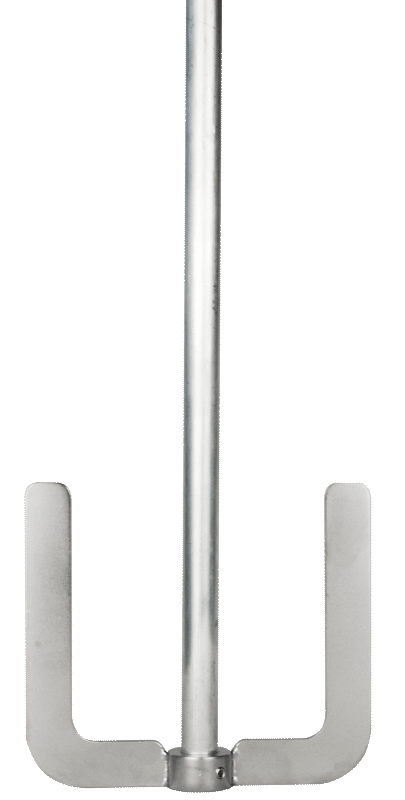

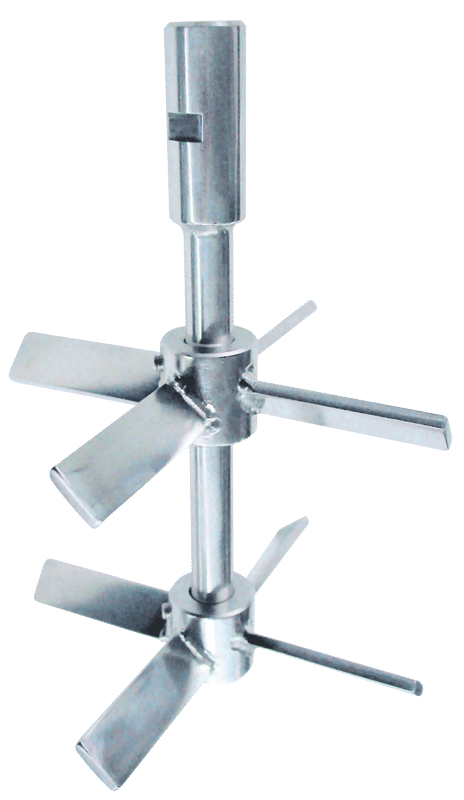

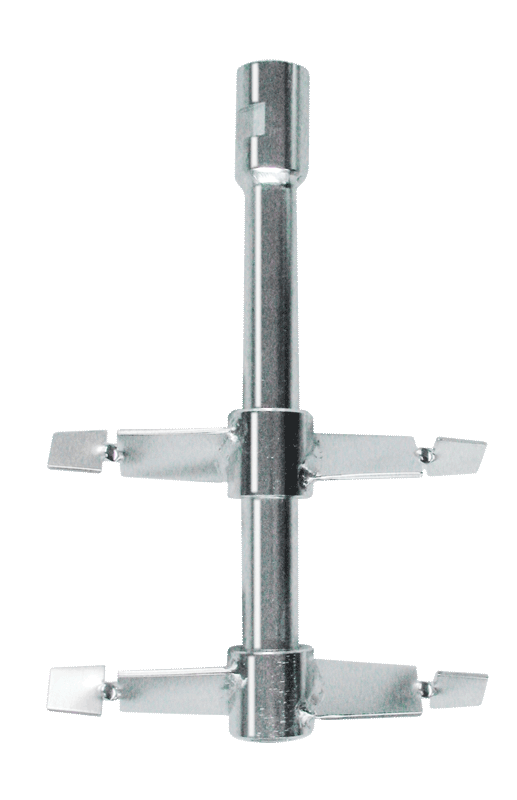

We manufacture all stirrer geometries for both cylindrical and conical stirrer vessels:

The right agitator

for each application.

Whether you need a simple anchor stirrer or a special gassing stirrer, we have the solution for you.

Proven stirring geometries

continuously developed.

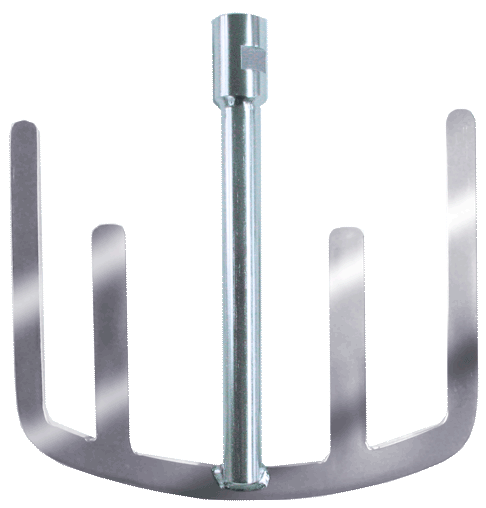

These stirring elements are available from us in stainless steel, Hastelloy or with a coating (tantalum or PTFE/PFA):

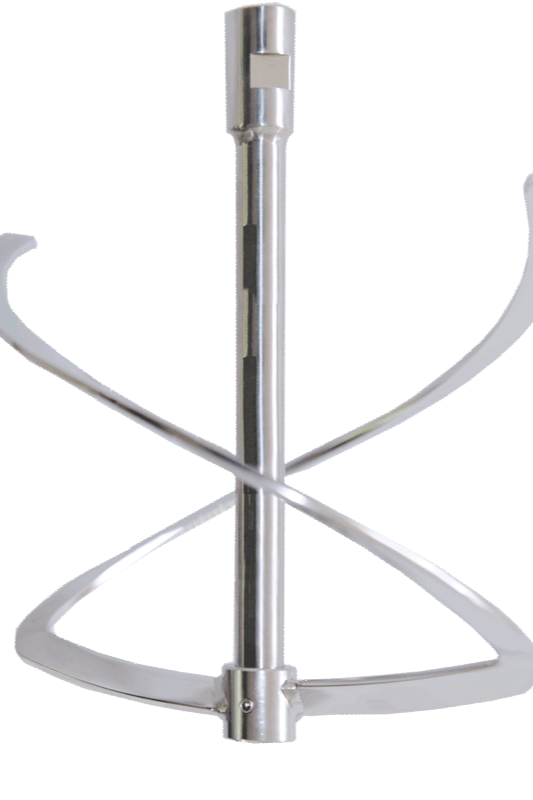

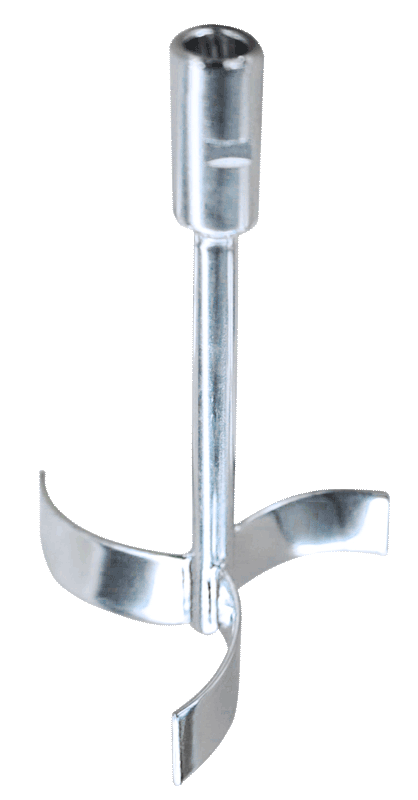

- Anchor stirrer

- Double anchor stirrer

- Helical anchor stirrer

- Spiral agitator

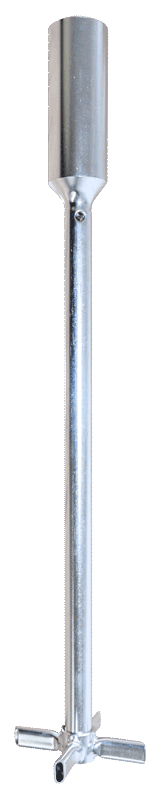

- (Adjustable) cross beam stirrer

- Impeller stirrer

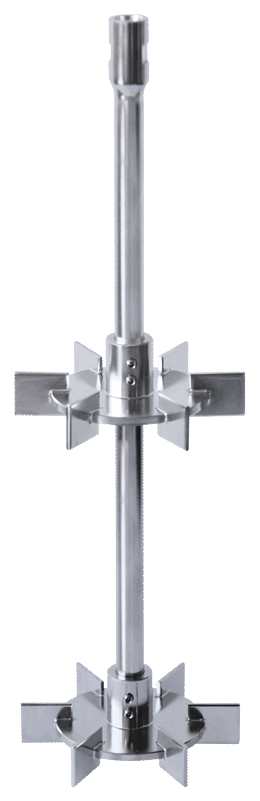

- Dispersing disk stirrer

- (Adjustable) Rushton turbine

- Intermixer

- Gassing stirrer

- + Special designs

We have what you need,

contact us!

lets talk about a solution for your application

stirring feedthroughs

stirring couplings, stirring caps

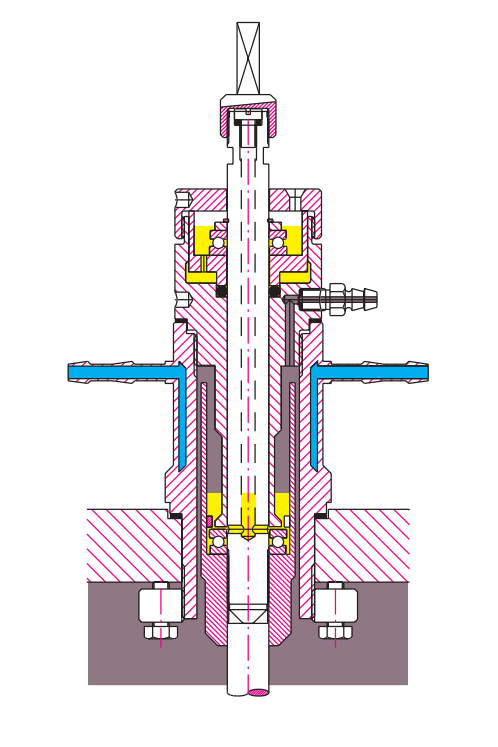

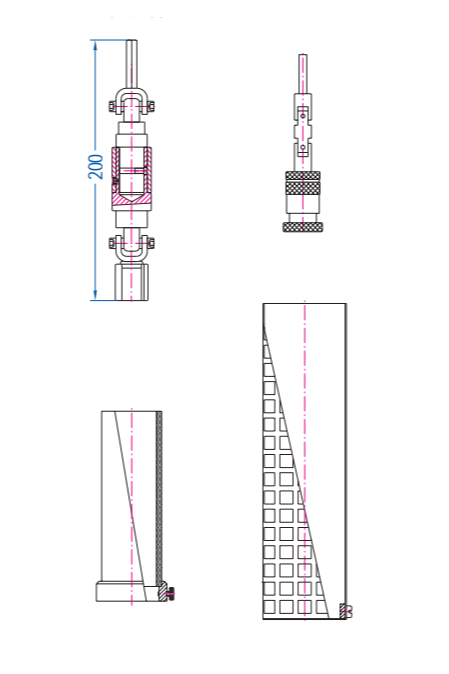

JUCHHEIM Stirring feedthroughs (also called stirring seals or stirring couplings) are a key component of a pressure or vacuum reactor. They are the first to make it possible to stir even in a pressure-bearing vessel, as they seal the rotating shaft or transmit the torque through the wall with strong magnets.

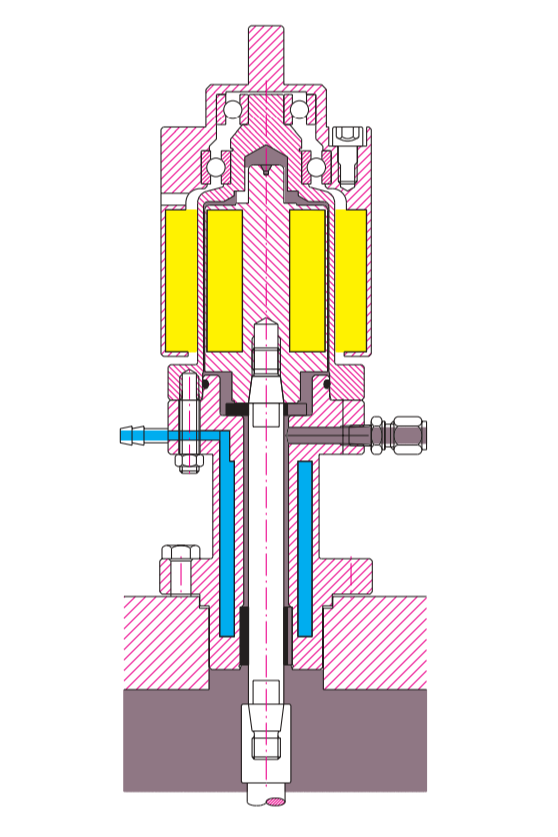

Wherever possible, we recommend a magnetic coupling for use in stirred tanks for process development or process optimization. Only this offers the unique advantage of a purely statically sealed system. However, for large vessels (approx. > 50 liters) or viscous media (approx. > 10 Pas) the transmittable torque can be limiting.

Our magnetic stirrer couplings transmit torques up to 32 Nm at up to 200 bar overpressure and 350°C working temperature. On request, we can also offer models for higher torques, which we can procure with the help of suppliers. Variants for high pressure and high temperature applications are also possible.

O-Ring

inexpensive and robust solution up to 25 bar

Magnet

Statically sealed system, torque transmission up to 64 Nm

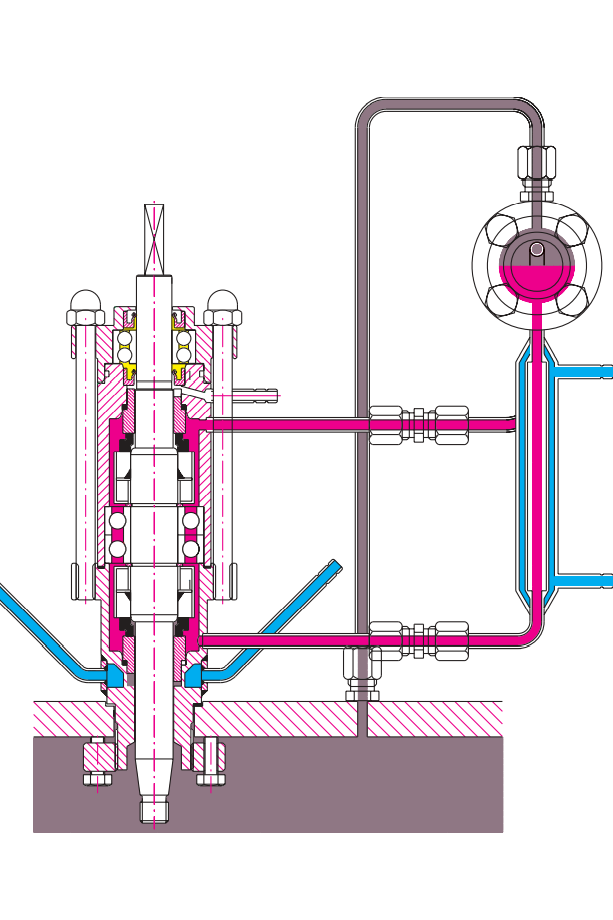

Sliding ring

Mechanical seal complete system up to 50 bar

Accessories / Service

Shaft cardan, contact protection and more

By the way: There are no limits regarding the connection dimensions. We are also happy to adapt our standard systems to your existing system.

The stirrer caps are manufactured in stainless steel (1.4571 or 316Ti) or Hastelloy.

The inexpensive solution up to 25 bar.

Agitator shaft coupling with O-ring.

Highest torque possible since transmitted directly via the shaft. The stirrer seals with O-ring or mechanical seal transmit several 100 Nm, depending on the model.

... and tight. With magnetic torque transmission.

From small to large. A few Ncm to 100 Nm. Can be used up to 350°C internal tank temperature thanks to integrated water cooling. Up to 200 bar, depending on the model. These systems do not require any lubricants at all. The replacement of the plain bearings is done in a few minutes.

Low maintenance and clean. Wet mechanical seal systems.

Mechanical seals made of graphite or silicon carbide (SiC) with integrated circulation cooling system (no additional peripherals required) also for GMP applications. Up to 50 bar.

Make the first step.

lets talk about a solution for your application

stirrer drives | motors

the little things make the difference

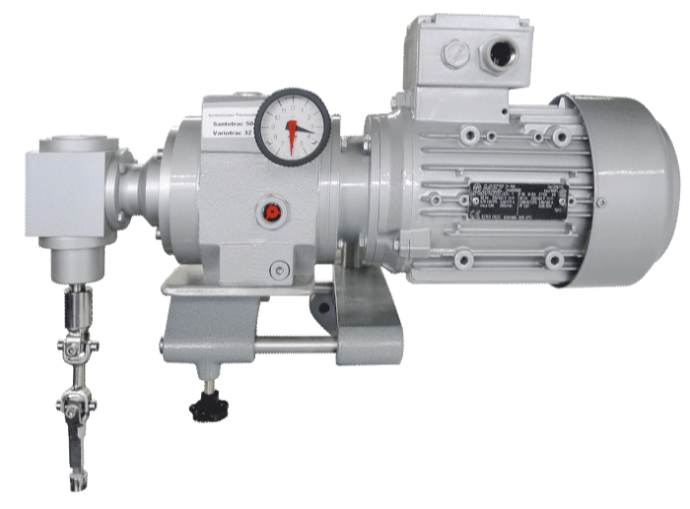

Our stirrer drives are equipped with continuously variable mechanical gears or electronic speed control. The electronic version can be controlled via an automation system.

The stirrer drives can optionally be equipped with torque measurement, which provides a torque-proportional signal for the automation system. This signal is very useful for tracking the course of the reaction and detecting reaction phases in polymerizations, for determining dissipation in the reaction calorimeter and for determining rheological material properties. In addition, the torque measurement is an essential parameter for scale-up experiments.

Translated with www.DeepL.com/Translator (free version)

A lot of power, used correctly.

ViscoVar™ stirrer drive with continuously variable gear.With three-phase connection for up to 100 Nm torque.

Right angle gearbox for reduced overall height.

Numerous Models Available, just let us know your requirements.

Make the first step.

lets talk about a solution for your application

Accessories

the little things make the difference

Often only the details lead to a really good solution. We will be happy to recommend the right accessories for your agitator tank.

You already have concrete ideas? Just share them with us. We also manufacture special solutions to order.

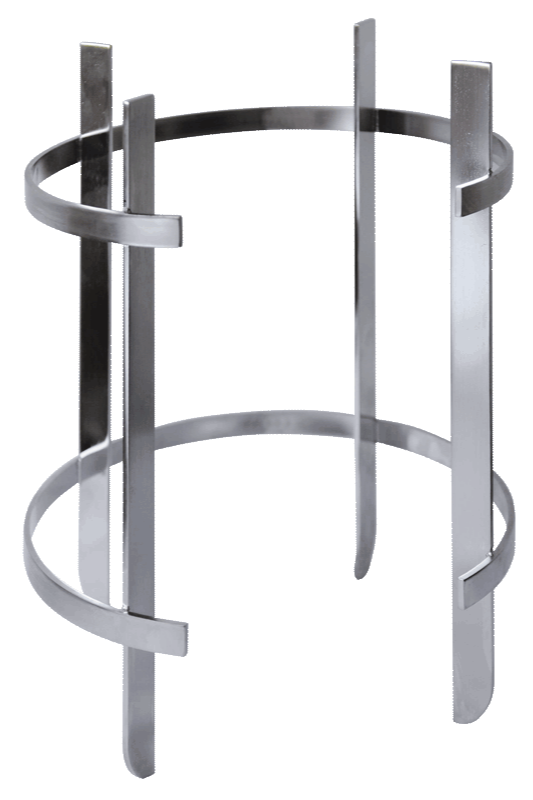

Retrofittable baffles

baffle for clamping into your stirred vessel up to an inner diameter of 700 mm.

Make the first step.

lets talk about a solution for your application